What’s the Controlled Inverter Energy Saving System of Oil Well Group?

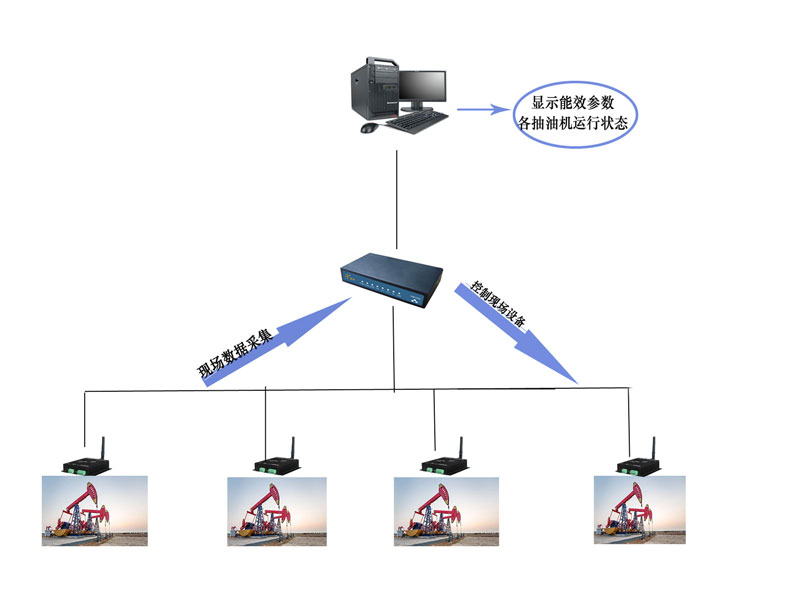

In petroleum exploitation, the oil well power supply mode has always used power supply at the oil production site with three-phase AC line to set up in the oil well, and then go through a single well transformer into a low-voltage, and then transmitted to the oil well start-up cabinet to control the motor operation. This technology is mature and easy to use. However, there are still problems such as high frequency converter failure rate and inefficient use etc. Moreover, the unbalanced power consumption of pumping unit in production results in the phenomenon of “reverse power generation”, virtually causing waste of electric power and loss of service life of equipment. The controlled inverter energy saving system of oil well group can change the decentralized control to the centralized control. The system transfers the low-voltage alternating current after the step-down of a single transformer to the direct current to each single well, and then the “reverse power generation” of each well pumping unit is transmitted to the power grid through DC bus. It has effectively improve the efficiency of power use while reducing the redundant waste of transformer. In addition, with the use of wireless remote transmission technology such as ZIGBEE, energy consumption data and production data for each single well can be transmitted to the monitoring terminal in real time; hence, the monitoring and automatic control of the oil wells can be achieved.